Company

Dr. Terry Brewer’s discovery of anti-reflective coatings resulted in a revolution in the global microelectronics industry and ushered in today’s high-speed, lightweight electronic devices.

Learn MoreAdvanced Materials

Advanced materials for the protection and enhancement of optics, displays, and other microelectronics.

Learn MoreLithography

Our line of products stretches across the whole spectrum of lithography wavelengths and is the most comprehensive product lineup in the industry.

Learn MoreSmart Devices

At Brewer Science, we are focused on delivering critical, real-time information to our customers to help them achieve their goals, solve their problems, and improve their current systems.

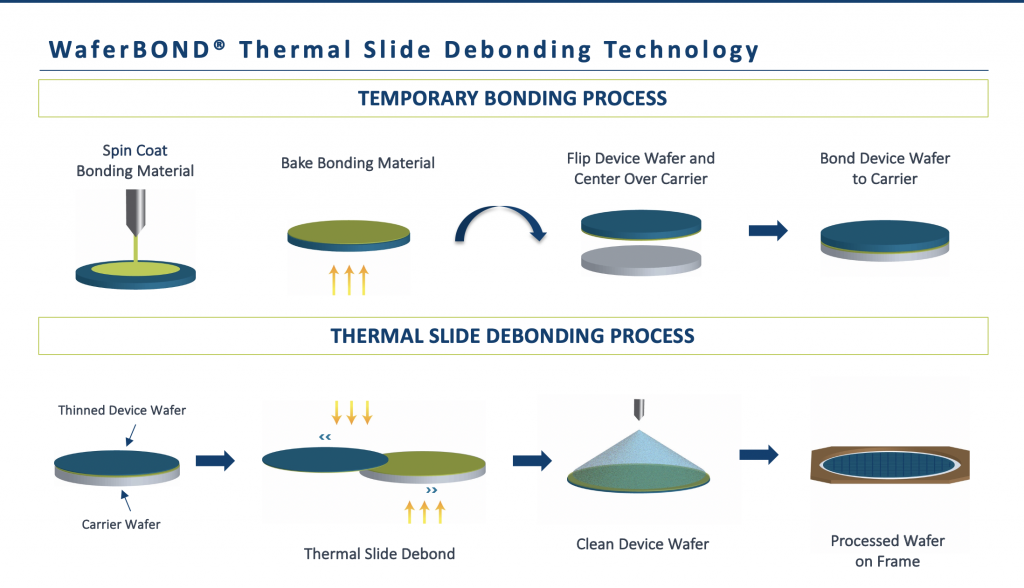

Learn MorePackaging Solutions

Brewer Science is revolutionizing packaging solutions with innovative bonding and debonding technologies.

Learn More